Setting up an efficient study can help you save time and allow you to get the most out of screening and optimization experiments during method development.

How to get the most value out of your experiments

- Questions to ask during method development:

- Is there a need to understand the impact of individual parameter settings when varied simultaneously and what would the combined effect of these settings be?

- What would be the best settings for these parameters to gain the most value out of our process?

- Can obtained data be used to predict the outcome when these parameters are varied and to determine optimal conditions for a number of process outputs?

At GE, Six Sigma tools are commonly used in development of products and production processes. One such tool is design of experiments (DoE). In our field, DoE is used in the development of processes for cell cultivation, protein separation, protein stability testing, analytical testing strategies, and in robustness testing of the developed process. Even though DoE probably is mostly used in the industry, it is a powerful tool to use also in research applications.

- Using DoE, we do not assume that the outcome is generated by changing the setting of one single, representative key parameter. Instead, we are trying to clarify:

- Which parameters affect the process?

- If the output depends on a combined effect of the studied parameters?

- If there is a nonlinear relationship between process inputs and outputs?

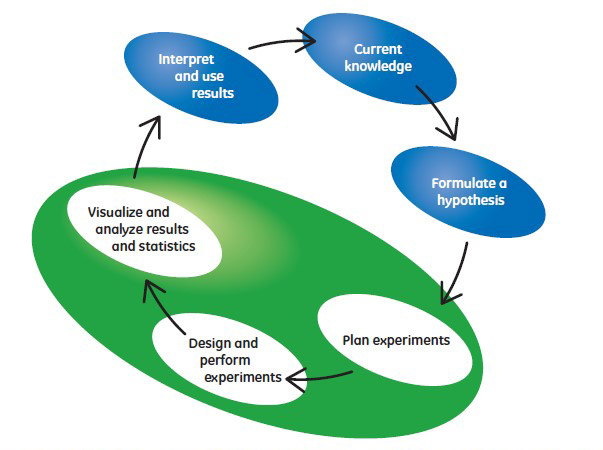

The use of modern software has facilitated the use of DoE as a standard tool for experimental planning. DoE software is used for designing experiments as well as data evaluation and visualization to describe in detail how a system or a process works. With DoE, meaningful and detailed data visualization can be produced to help create faster processes, provide better end results, and to give more insight into the process (Fig 1).

Fig 1. Schematic overview of the statistical contribution of DoE (green) to the iterative research process.

Essentially, DoE is a way to systematically vary several parameters simultaneously to obtain sufficient information, with as few experiments as possible, to enable development of an optimized and efficient process. In DoE, the high and low settings for all input parameters provide more information about the input-output relationship than varying experimental conditions one-by-one, while keeping other parameters fixed. The study setup using, so called, corner points with the high and low parameter settings, allows detecting parameter interactions that will affect the process output. Multiple linear regressions are one standard modelling tool used to determine relationships in the data. The use of mathematical modelling allows us to describe and display the combined influence of all input parameters. In a model of a studied process (e.g., a protein purification protocol or a chromatography step), we try to understand how the process is influenced by the experimental parameters. The models we create with DoE will help us define regions where desired outcome can be achieved.

Learn more about how to benefit from DoE study setups from the handbook Design of Experiments in Protein Production and Purification