Chromatography options for flexible and intensified protein purification

The main technique for chromatographic purification in today’s pharmaceutical industry uses highly porous microscale beads. These beads have a functionalized surface to allow discrimination of drug product from the complex process stream. For example, with a protein A ligand on the bead surface, monoclonal antibody (mAb) purification is mediated via an affinity interaction.

But as the biopharmaceutical market continues to evolve and grow to adapt to clinical and economic drivers, there is an increasing need to intensify processes and make facilities more flexible. To address these growing needs, new technologies that increase productivity and are economical in single-use operation are required across unit operations. This scenario has led to the exploration of alternatives to porous beads.

One such technology is Fibro, which uses a proprietary structure that overcomes the diffusional and flow limitations of packed bed chromatography purification systems. It also aims to address capacity issues of chromatography membranes, which are mostly limited to contaminant capture steps. The new adsorbent material has the potential to improve process flexibility and robustness while meeting the demands of the rapidly changing biopharma landscape.

Fig 1. The macroporous and high surface area of the fibers enables convective mass transfer and high binding capacity.

MabSelect PrismA ligand – next-generation protein A

The recombinant protein A ligand has enabled the era of antibody biopharmaceuticals by allowing different antibodies to be purified using the same approach, achieving more than 99 percent purity in one step. Although protein A was discovered in the 1960s, it was not until the 1980s that it started to be widely used in the industrial purification of antibodies.

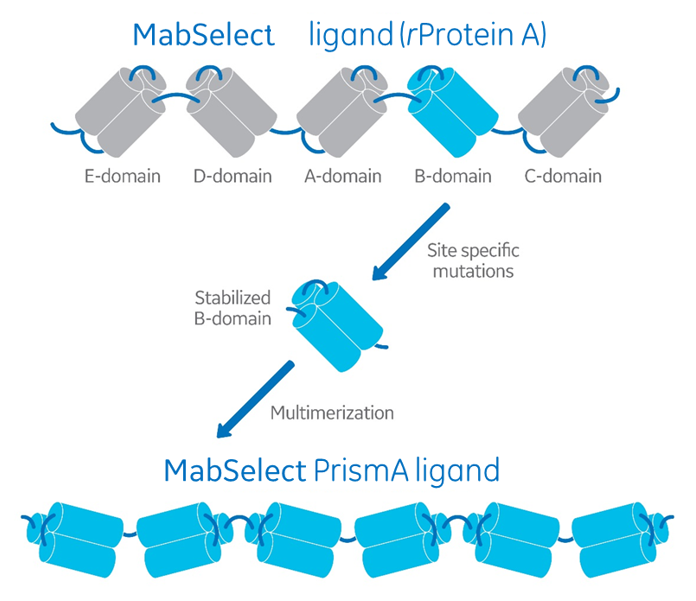

The development of protein A technology has mirrored the needs of the industry, first by removing animal-based components from the production of protein A and then by improving the pressure/flow properties of the chromatography bead. In 2005, the first alkali-stable protein A resin, MabSelect SuRe , was commercialized. This resin advanced protein A technology even further by dramatically extending the lifetime of Protein A resin and thereby reducing the cost of mAb purification. Most recently, MabSelect PrismA resin was developed to address the needs of higher titer cell cultures by improving capacity and alkaline stability (Fig 2).

Fig 2. Protein A ligand engineering to improve capacity and alkaline stability.

The ligand was developed using high-throughput screening to identify amino acids sensitive to alkaline degradation, so they could be substituted with more stable ones. The first screening was performed on monomers, and the most promising constructs were multimerized into stabilized ligand constructs. More than 400 constructs were screened with the Biacore system, which is used for high-quality characterization of molecular interactions.

Exploration of chromatography adsorbents for protein A

Despite its effectiveness, protein A ligand is costly. This cost is due to the fact that protein A is derived from a recombinant production process and must be purified prior to use in biotherapeutic manufacture. Therefore, to utilize the protein A ligand effectively, the adsorbent material must have a high surface area-to-volume ratio to efficiently capture as much antibody as possible in the smallest physical volume. This surface area must also be accessible to large protein targets, as monoclonal antibodies are about 5 nm.

Further, ligand utilization depends on the time to complete a purification cycle, which includes product binding and elution plus multiple wash and conditioning steps. Thus, productivity is a function of the amount of product that can be purified per unit of time and per unit of adsorbent. It is also a function of the ability to reuse the resin over multiple cycles.

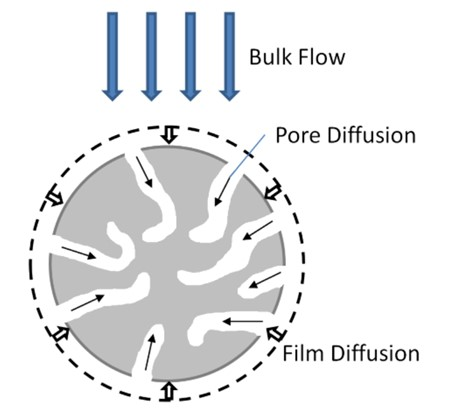

Bead-based chromatographic adsorbents are highly porous, with most of their ~ 40 m2/g surface area hidden within the inner structure. Thus, the target antibody carried in the bulk feed medium must go through two stages of mass transfer before reaching the functional binding surface buried deep within the pores of a chromatography bead, as shown in Figure 3.

Fig 3. Schematic of mass transfer in a porous bead.

The initial film diffusion takes place, followed by diffusion into the porous structure. This transfer requires sufficient residence time, resulting in a flow rate-limited operation, because faster flow rates reduce binding capacity and productivity. Diffusion then presents a fundamental barrier to improving purification productivity using beads.

Also, because the bead support structure is compressible, increasing the flow rate reduces the interstitial void and thereby increases the back pressure. Above a critical limit, this compression causes irreversible mechanical damage. For industrial-scale operations based on beads, residence times of 3 to 12 minutes are used, leading to a cycle time of 6 to 8 hours. As mentioned previously, resin is often used over multiple batches to make the process cost effective.

Monolith and membrane technologies that operate by convective mass transfer do not rely on diffusion. This means they can be operated at lower residence times and higher flow rates. But monoliths and membranes have limited surface area available. As a result, they are often used in scenarios where capacity is less critical, such as near the end of the purification chain when low levels of contaminants can be pulled out by these adsorbents. To increase the productivity of product capture steps such as protein A, new adsorbents are needed to combine a high flow rate with rapid mass transfer.

Fibro technology

Fibro adsorbents were designed to address this need. The fiber structure is highly open to facilitate mass transfer without diffusion, similar to membrane and monolith technologies. Unlike those options the Fibro structure provides a large surface area as a result of its additive manufacturing process called electrospinning. First, an electrical charge is applied to the polymer solvent solution, which leads to self-repulsion due to the induced electrostatic charge. This charge results in the formation of jets from the polymer solvent solution. The solvent dries off, and the charge migrates to the surface of the polymer, causing a rapid acceleration through a whipping process; the fiber diameter decreases as the fiber spins out (Fig 4).

Fig 4. Illustration of fiber formation by electrospinning.

Fibro material uses a long hydrocarbon chain-linked polymer. The long chains become entangled and cannot separate from one another, which keeps the polymer structure intact and forms the fiber. Each fiber layers randomly on top of another to form a structure that resembles a ball of yarn or spaghetti. This process creates a material with a very large surface area, ~ 10 m2/g compared to ~ 0.7 m2/g for traditional porous cast membranes. The Fibro production process creates homogeneity and properties that allow rapid mass transfer to the surface.

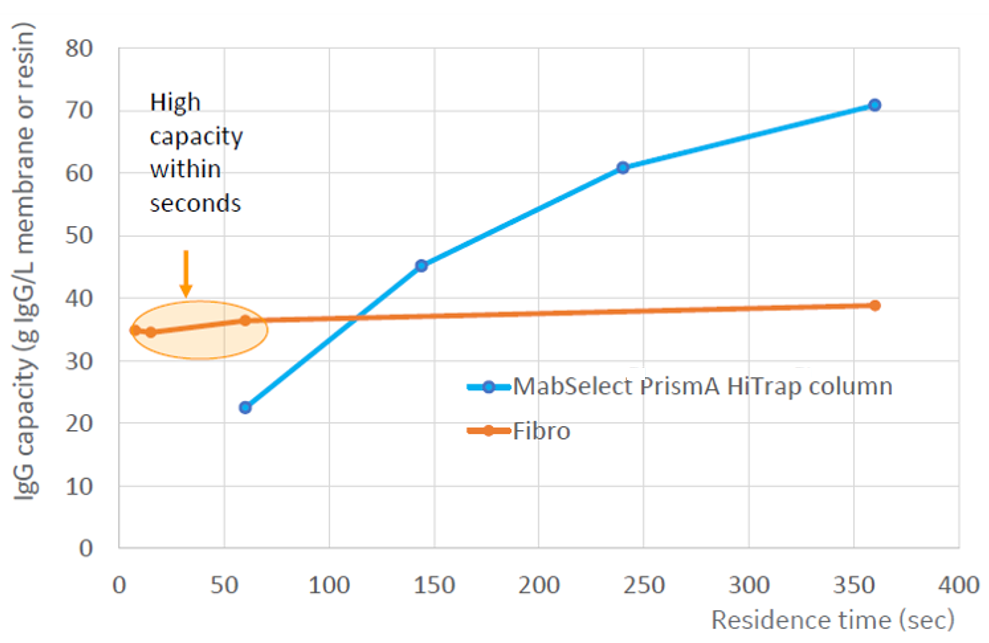

Fig 5. Fiber technology allows high dynamic binding capacity at short residence times.

Figure 5 compares performance of the Fibro technology and porous resins functionalized with the same ligand. Although the surface area of Fibro (~ 10 m2/g) is lower than that of the bead (~ 40 m2/g), the binding capacity is higher at short residence times. As the residence time increases, there is more time for diffusion to take place, and the bead capacity increases. However, the Fibro capacity remains largely constant, adding further support to the case that the binding is minimally impacted by residence time due to a highly accessible surface area.

The ability to operate Fibro at short residence times has significant impact on an industrial scale. Rather than taking 6 to 8 hours to perform a cycle on a bead column, a Fibro cycle can be completed in around 5 minutes. This means that, with a large enough fiber technology unit, a chromatography step could be run in just 2 or 3 minutes instead of the 1 to 5 days required today. The ability to complete full chromatograms in just minutes using fiber adsorbents allows for rapid column recycling. Fibro could complete hundreds of cycles in the same amount of time it takes to run just 1 or 2 cycles on a normal column at large scale. Productivity such as this would shrink the operational footprint considerably.

Finally, by enabling the full amortization of the cycle lifetime of the protein A ligands, Fibro effectively turns the protein A step into a single-use operation. Fibro also offers flexibility that will be beneficial in continuous manufacturing, because an end user can change the feed-flow rates to adapt to upstream process variation while maintaining purification performance.

A high-productivity technology for the future

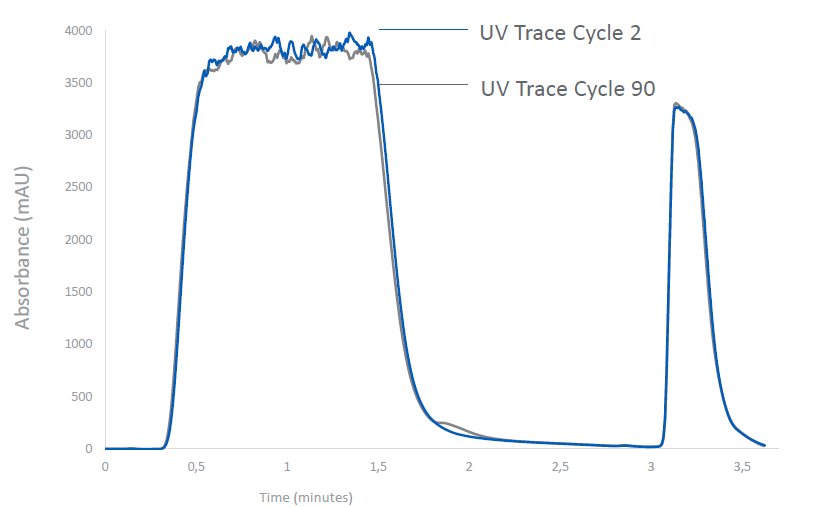

To demonstrate scalability and reproducibility of the Fibro technology a representative mAb was purified over 90 cycles on a 40 mL fiber adsorbent unit. Figure 6 shows the conformity of the chromatogram UV trace for cycles 2 and 90. Over a 6 hour period, 114 grams of mAb were produced.

Fig 6. Chromatogram showing the same performance over the lifetime of a rapidly cycled Fibro unit.

In terms of productivity, nearly 500 grams of mAb were purified per liter of adsorbent per hour. In contrast, traditional bead columns produce only about 10 grams per liter per hour. Highly productive chromatography processes are needed as biomanufacturing moves toward smaller batch sizes with annual production rates below 150 kilograms and a dramatic increase in upstream titers, which puts new demands on bioprocessing manufacturing design.

Multiproduct facilities with easy and fast changeover between campaigns have become more important, driving the adoption of single-use technologies. Also, increased upstream titers put extra pressure on downstream operations where better productivity is required. This has resulted not only in recent developments of high-capacity resins but also in the adoption of continuous chromatography. Flexible facilities that use scalable technologies reduce process development risks during manufacturing handover by allowing biomanufacturers to delay capital investment until they know how their drug will perform on the market.

In developing the technology, we have worked with over 50 different mAbs from small and large collaborators across the globe. In every case, the quality of the product produced from the Fibro purification process matches the quality produced by existing protein A technologies, due to the enormous power of the PrismA ligand combined with the unique Fibro design.

In the past biomanufacturers have called for new technologies to replace protein A chromatography. However, due to its effectiveness, protein A is nearly universally employed for mAb manufacture. Instead of replacing protein A chromatography, Fibro offers a step-change in its productivity, which is expected to extend the use of protein A for platform processes for many decades to come. Critically, for those working with newer biological targets, we expect that Fibro will ultimately be combined with a wide range of ligands and functionalities, making it relevant to other key areas, such as the purification of viral vectors.