Packing a chromatography column is an art in itself and requires a certain level of expertise. Here, we provide definitions for common terminology used in column packing.

A

B

C

Depending on the column type and resin, the compression may be performed in two different ways:

Mechanical compression with packing factor:After applying the settling flow, note the height of the consolidated bed before stopping the flow (after the flow is stopped the bed can slightly expand). The final bed height is calculated by dividing the consolidated bed height with the packing factor (PF):

Final bed height = Consolidated bed height/packing factor (PF).

Set the adapter against the consolidated packed bed, tighten the O-ring, and turn the end cap down until the calculated final bed height is reached.

Flow compression:After applying the packing flow, the adapter is moved a specific distance (mm) into the packed bed to avoid gap formation.

CF is defined as the settled bed height (bed height measured after settling by gravity, L settled) divided by the packed bed height (Lpacked), that is, CF=L settled/ Lpacked

Bed height measured after settling the resin at a given flow velocity.

The pressure at the critical velocity.

The highest velocity possible to obtain in an open bed. The procedure to determine Vcri is described in Development of column packing methods based on pressure-flow measurements

E

High efficiency means that the band broadening is low (= sharp peaks will be obtained). It is often given as the number of theoretical plates (N) or as theoretical plates per meter (N/m) in order to be a measure independent of column length used for the experiment.

It plays a central role in the qualification and monitoring of packed bed performance. The desirable high column efficiency gives low band/peak broadening and is an indicator of how well packed the column is before starting purification.

Column efficiency is typically defined in terms of two parameters:

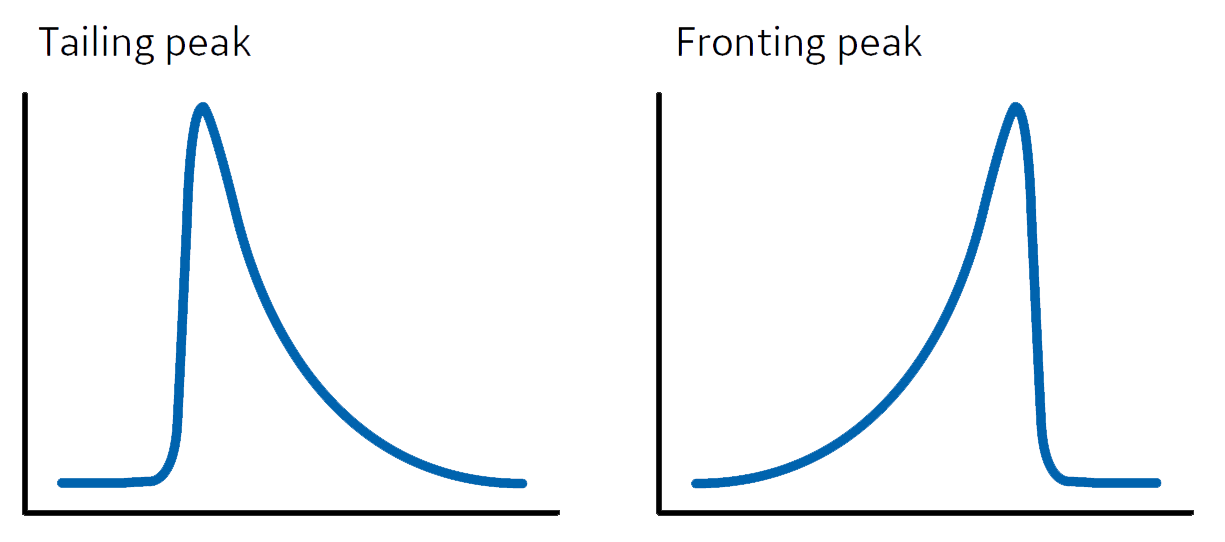

- Peak broadening over the column is described by an equivalent number of theoretical plates.

- Peak symmetry is described by a peak asymmetry factor, As.

The procedure to determine column efficiency is described in each Cytiva resin protocol and is also described in this Column efficiency testing application note.

F

H

M

O

P

A measure of chromatography peak broadening/column efficiency. Also referred to as number of theoretical plates. The plate number of a column is used to measure column efficiency. The more plates a packed column has, the higher the column efficiency. The plate number is calculated from N = 5.545 × (VR/Wh)2 assuming a Gaussian peak, where VR = retention (elution) volume and Wh = peak width at half peak-height. VR and Wh must have the same unit (e.g., mL). VR may be substituted in the formula with retention time, tR, but then the unit of Wh must be time.

See also Plate height/height equivalent to a theoretical plate and Reduced plate height. See Efficiency as well.R

S

Resin slurry

Resin particles suspended in liquid.

Slurry concentration

The slurry concentration is used to facilitate the calculation of the amount or resin needed to pack a certain bed height. For successful packing, different resins require different slurry concentrations. To determine the slurry concentration for large columns (approx. > 5L), we recommend that you use the Slurry Concentration Kit. You can also watch our video Column packing tutorial: Determining slurry concentration using a slurry kit. For small columns, other methods involving centrifugation and/or sedimentation are also possible to use.

How to calculate the amount of resin slurry that is needed to pack a column?

Follow the following steps.

| Steps | Description of each step | Example: Packing Capto Q in an XK 16/20 column (10 cm bed height) |

|---|---|---|

| 1. Define the volume to take from the resin bottle (Vs). | The volume of the initial resin slurry1 to take from the bottle is calculated according to the following formula: Vs = (Vc/Cs) × CF where

| According to packing instructions

So, 31 mL of the initial suspended slurry should be taken from the supplied resin bottle. |

| 2. Wash the initial resin slurry into the packing solution |

|

|

| 3. Adjust the slurry concentration |

|

|

T

See also Plate height/height equivalent to a theoretical plate and Reduced plate height. Also see Efficiency.