Bioprocess equipment regulation lags behind innovation

Single-use technologies offer many benefits compared with traditional stainless steel equipment, such as speed to market, operational flexibility, and reduced capital expenditure. One of the challenges is that there are no specific regulations for these innovative technologies and their use in biologic manufacturing. This regulatory uncertainty can leave biomanufacturers questioning how to be sure the single-use equipment they purchase will be appropriate for making their therapeutic molecule.

Why regulation is needed

Biomanufacturers must comply with strict regulatory requirements dictated by the relevant medical agencies. In order to meet these requirements, the biologics they make have to work as intended. Key attributes of biologicals related to safety and efficacy often depend directly on the manufacturing process. Biomanufacturers need to ensure that the molecules they produce will maintain their critical quality attributes (CQA) regardless of the process conditions, equipment, or materials used to make them.

Until regulations that apply solely to single-use biomanufacturing processes are developed, biomanufacturers will take different approaches. But all stakeholders, from regulators to end users, still expect biologics manufactured with single-use technologies to meet equally high standards as biologics produced with traditional stainless steel equipment.

So until specific regulations are in place, what is Cytiva doing to assure both end users and regulators that single-use equipment is fit for purpose?

Meeting industry requirements

In the absence of regulatory certainty, Cytiva is dedicated to producing single-use technologies with the required attributes and documentation for successful use in biomanufacturing.

Our principles

- Understand why issues are important from a biomanufacturer’s risk mitigation perspective

- Participate in the evolution of thinking on how to manage the quality of single-use technology

- Provide data packages that are convenient and straightforward for end users

- Have subject matter experts to manage various aspects of quality, such as integrity and extractables

How Cytiva ensures quality of biomanufacturing technology

Because every stage in the manufacturing process is crucial to product quality we have a multi-layered approach to ensuring the quality of our technology. All our biomanufacturing equipment and processes are designed to meet standards already in place such as:

- applicable regulations from medical agencies, such as the US Food and Drug Administration and the European Medical Agency

- legal requirements like EU directives and regulations for handling potentially hazardous material

- import/export regulations

- licenses for chemicals

We also keep strict control over all raw materials used to make our bioprocess equipment. We know the source and origin of these raw materials. We have set up procedures that ensure the security of supply of critical raw materials and avoid potential contamination. As a part of our quality management system (QMS), we can account for and show the process controls in place to protect raw materials.

Safety measures for single-use equipment and hardware

The key to the safety of single-use technology is making sure that relevant guidances from the FDA and other agencies are followed.

US Code of Federal Regulations, 21 CFR 211.65 “Equipment shall be constructed so that surfaces that contact components, in-process materials, or drug products shall not be reactive, additive, or absorptive so as to alter the safety, identity, strength, quality, or purity of the drug product beyond the official or other established requirements.”

FDA CDER "Container closure Systems for packaging human drug and biologics” 1999: A drug is deemed to be adulterated "if its container is composed, in whole or in part, of any poisonous or deleterious substance which may render the contents injurious to health..."

These guidances apply not just to the primary packaging of drugs but also to the containers for bulk drug substances. We carefully follow these guidances for all our bioprocessing components and equipment–including single-use.

Customer requirements are also core to our approach to supplying equipment for biologics manufacturing. For example, we follow US Pharmacopeia and international (ISO) standards for polymeric materials.

Extractables and leachables

Because there are no specific regulatory requirements for extractables testing of single-use equipment, you will find that suppliers are using different protocols. These differences make it tricky for customers to interpret the resulting information.

To avoid these issues, the BioPhorum Operations Group (BPOG) put forward a proposal for a standard approach to testing, and they published a protocol. We’ve now brought our own protocol in line with the core elements of the BPOGprotocol. All new products are tested in accordance with this protocol. We are also working our way through updating existing commercialized products, starting with components that contain our new single-use platform film, Fortem.

Download the white paper: Single-use extractables and leachables: Cytiva's alignment with the BPOG protocol

Regulatory documents at your fingertips

If you need regulatory documents for our bioprocessing technologies, you can easily get them online. All of our bioprocess chromatography resins and single-use technologies have a Regulatory Support File (RSF). The RSF contains detailed information on performance, stability, extractable compounds, and analytical methods.

Our single-use hardware has a similar document, a Validation Guide (VG) . The VG has information about the manufacturing process, product stability,and extractables. UNICORN software has a Validation Support File (VSF), in compliance with GAMP5, CFR Part 11,and EU GMP Annex 11 guidelines.

A robust Change Control Notifications (CCN) process is in place for chromatography resins and single-use products used in bioprocesses.

Every time new information for a RSF, VG, VSF, or CCN is published on our website,we will let subscribers know via email.

If you have specific questions on shelf life, animal origin, or need a questionnaire completed, our regulatory team can support you. Contact us

Collaborating with industry leaders on best practices

As an indication of how seriously we take these issues,we are part of the Biophorum Operations Group (BPOG),a cross-industry collaborative group sharing operational best practice in drug manufacturing and bioprocessing. We are part of several working groups and are continually reviewing our practices to ensure they meet the latest thinking and align with BPOG's protocols.

We also look carefully at regulatory environments in different parts of the world and ensure we meet applicable local regulations. We strive to evolve and provide inputs as required by local regulators,helping to bring everyone up to the highest possible standards.

The future state and your part in it

The future

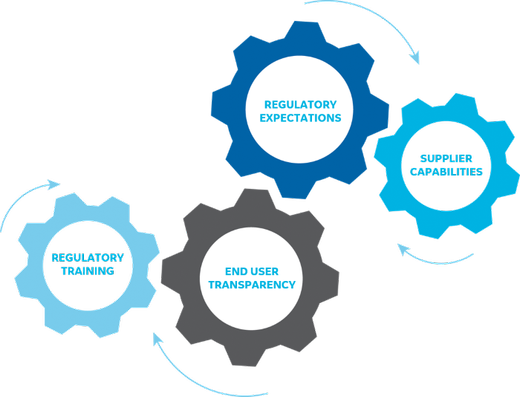

New ways of working and regulations develop as technology and standards evolve, bringing better results for everyone involved. Risk-based approaches will mature and regulatory agencies will refine and clarify their expectations and policies. Innovation and evolution will be beneficial for all stakeholders.

How end users can help

- Share application information for single-use equipment with suppliers

- Help suppliers to understand why you have a requirement

- Participate in the evolution of thinking about ways to manage the quality of single-use technology

If you want to find out more about how Cytiva can help you meet single-use regulatory requirements,please contact us. We'll be happy to help. Contact us

See how to create biomanufacturing capacity with single-use technologies in just 14 months.

Find out how Fujifilm Diosynth Biotechnologies and Cytiva created efficient solutions.

- See how we collaborated together

- How we did it and lessons learned – a presentation

- Download our single-use solutions brochure