| KUBIo modules: | |

|---|---|

| Floor 1 | Operations area |

| Floor 2 | Gowning areas and HVAC installations |

| Production area standards | Biosafety level 1 (BSL1) |

| mAb output capacity** | |||||

|---|---|---|---|---|---|

| KUBio configurations* | Building footprint | Total space | Titer: 2.0 | Titer: 3.0 | Titer: 4.0 |

| 2 x 500 L | 1200 m2 | 2200 m2 | 28 | 42 | 56 |

| 2 x 1000 L | 1200 m2 | 2200 m2 | 56 | 84 | 112 |

| 2 x 2000 L | 1350 m2 | 2400 m2 | 112 | 168 | 224 |

| 4 x 2000 L | 1400 m2 | 2650 m2 | 224 | 336 | 448 |

**Assumptions: 70% recovery through purification, 20 batches per year, per reactor.

Q. What is the difference between KUBio and FlexFactory?

A. KUBio is the complete cGMP-compliant solution, offering the facility to house bioprocessing manufacturing, and the equipment needed. FlexFactory is the bioprocess platform used inside the facility. The platform is designed with predominantly single-use technology. It comprises distinct unit operations connected via single-use tubing sets and can include a variety of automation schemes. It can also be installed into new or existing workspaces.

Q. Which biologics can be manufactured in a KUBio?

A. Biologics such as mAbs or vaccines can be manufactured on a FlexFactory platform in a KUBio facility.

Q. How much experience do you have in setting up KUBio facilities?

A. There are KUBio units already successfully operating in Wuhan, China with more currently in production – including another in China and 4 destined for Cytiva BioPark in Cork, Ireland. If you have questions about installing and running KUBio facilities, please

contact us.

Q. What are the advantages of KUBio over building traditional-style facilities?

A. KUBio facilities are between 25% and 50% more cost-effective to build than comparable traditional facilities. Also, they can be up and running in 18 months, enabling improved access to drugs around the world. They also consume significantly less water and energy than facilities using traditional stainless steel technologies.

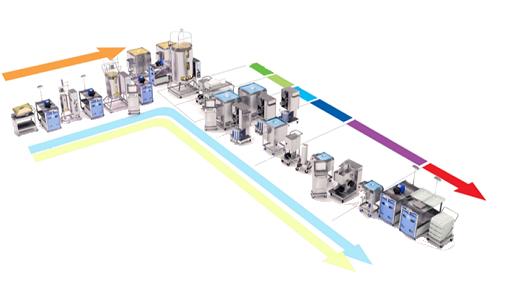

Q. What equipment is included in the KUBio's FlexFactory platform?

A. The FlexFactory platform will be planned and created to suit your needs. Typically, it will include:

- WAVE Bioreactor systems for cell culture expansion and Xcellerex XDR bioreactors for seed bioreactors and production bioreactors.

- ÄKTA chromatography systems for protein purification operations.

- Xcellerex XDUO and XDM Quad Mixing Systems to automate the mixing of buffers, media, and product intermediates.

Q. Does Cytiva offer financing options?

A. We provide advisory services to assist with project development and financing.

Q. Where can I find out more about KUBio?

A. If you are interested in KUBio, please get contact us to discuss potential options.