FPLC is an acronym for fast protein liquid chromatography. The term FPLC was coined and introduced by GE Healthcare (formerly Pharmacia) in 1982 and was originally referred to as fast-performance liquid chromatography as an opposite to high-performance liquid chromatography (HPLC). FPLC is used by researchers working in laboratory or preparative protein purification scale. FPLC systems are useful in purifying proteins, peptides, and other biomolecules with the objective of achieving desired purity and yield in a consistent manner. Automation allows process consistency and time savings to enable researchers to quickly prepare for the next research step.

Automated FPLC systems

It is important to distinguish FPLC from HPLC (previously acronym for high-pressure liquid chromatography). HPLC is intended for molecular analysis or characterization, while FPLC is used for protein purification at relatively low pressures and flow rates. Equally important as selecting the right technique, is selecting the right system suitable for the intended use and application.

Today’s FPLC systems are quite advanced, with a high level of automation. A number of benefits can be derived from using automated protein purification systems:

- Ensure more controlled conditions to achieve reproducible results.

- Purify proteins automatically without the need for user intervention during the run.

- Allow sensitive and low-expressed proteins to be purified more efficiently.

- Allow use of high-resolution chromatography media.

- Provide inline detection that helps in making informed decisions, for example, when the column has become equilibrated, when to collect fractions, etc.

- Allow automated collection of purified protein in choice of tubes and in desired volumes.

- Use software that makes it easy to create methods, monitor runs, and evaluate results.

ÄKTA systems from GE Healthcare

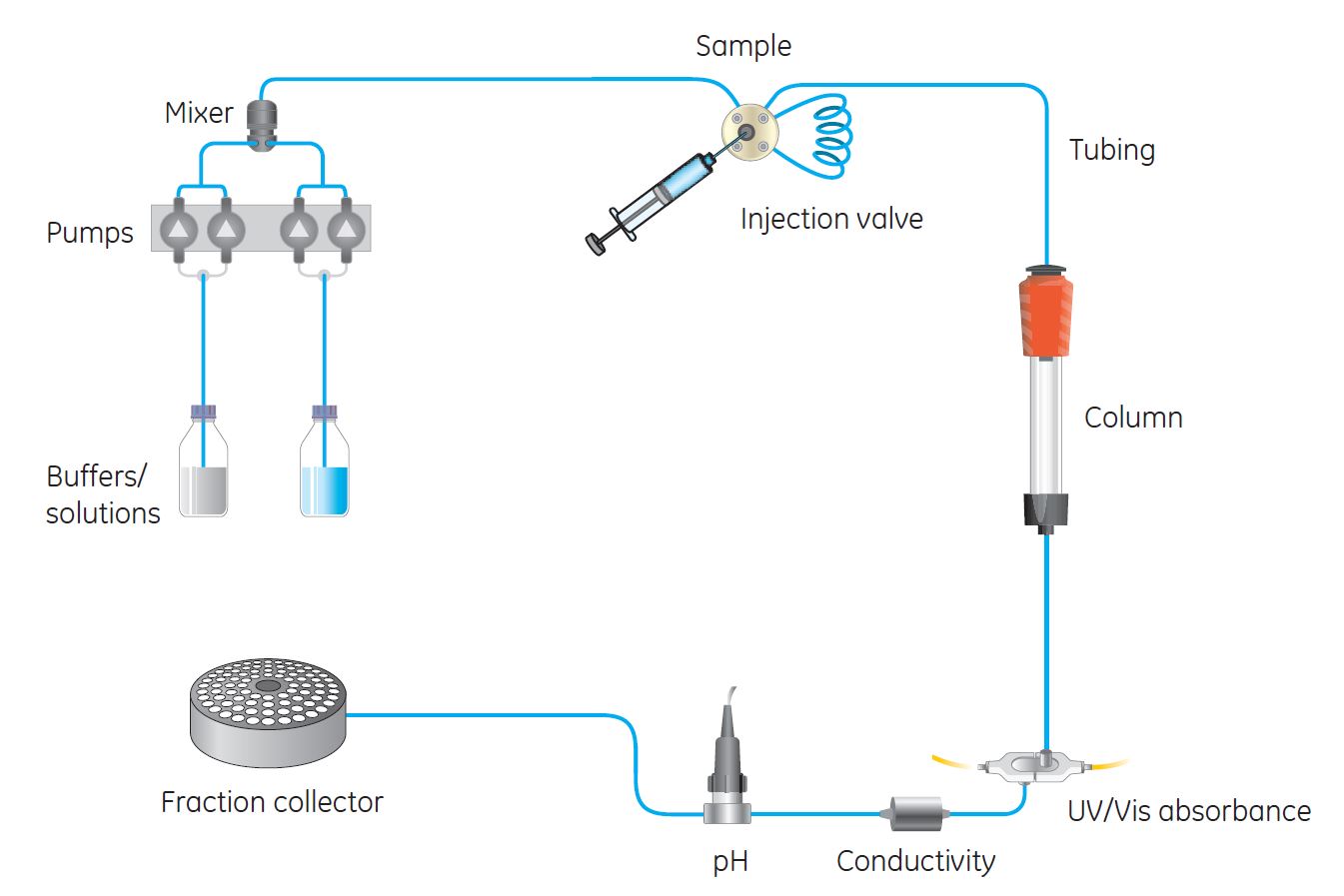

Protein separation takes place in a column. Buffers and other liquids are delivered via the system pump, and samples can be applied in different ways (e.g., using a syringe to fill a sample loop or by using a sample pump). Detectors (e.g., UV/Vis absorbance, conductivity, and pH) are placed after the column to monitor the separation process. Purified protein is collected in the fraction collector.

FPLC systems from GE Healthcare go under the ÄKTA brand. All ÄKTA laboratory-scale protein purification systems are easy-to-use benchtop chromatography systems, designed to support your research by providing speed, performance, and flexibility.

Standard ÄKTA system configurations

Learn more about our ÄKTA systems and how they can support you at every scale.